Die Casting in Malaysia: A Cornerstone of Precision Manufacturing

Die Casting in Malaysia: A Cornerstone of Precision Manufacturing

Blog Article

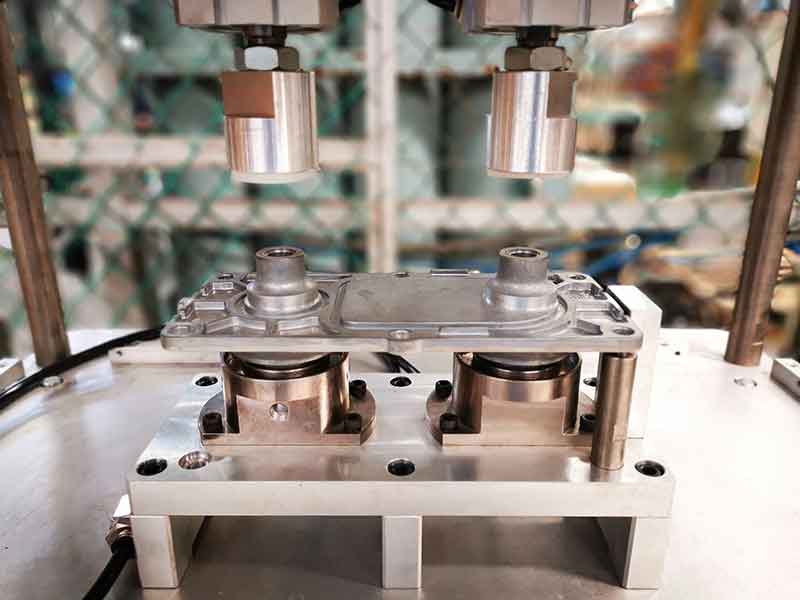

Die casting is now regarded as a cornerstone of manufacturing with precision and Malaysia has become an important player in this field. The process, which involves inflating the molten metal inside a mold under high pressure, produces robust and complex components that are used across various industries. The die casting industry in Malaysia is a major contributor to important sectors like automotive, electronics, aerospace, and construction, ensuring top-quality manufacturing standards and innovative. With a reputation for precision and efficacy, Malaysian manufacturers are meeting requirements both locally and internationally. The industry is thriving and plays crucial roles within the country's industry environment, which combines modern technology and sustainable methods to keep pace on the international market.

Die casting's flexibility is among the main factors driving its success in Malaysia. It allows the manufacturers to create complex shapes with remarkable precision. This makes the process indispensable to industries that need intricate designs. For the automotive industry in particular die casting is employed to produce lightweight yet robust components that enhance the performance of vehicles and improve the efficiency of fuel. In the electronic industry, this method is used to make housings, heat-sinks and various other vital components. The versatility of die casting ensures its widespread application which makes it an essential part of Malaysia's manufacturing infrastructure. With cost-effective solutions that do not losing quality, Malaysian companies have become trusted suppliers for clients around the world.

The strategically located location of Malaysia as well as its excellent infrastructure has made it an attractive destination for companies that manufacture die casts looking to serve both the international and regional market. It has modern equipment and skilled workers, enabling manufacturers to meet the strict quality standards demanded by industries like automotive and electronics. In addition, Malaysia's extensive supply chain as well as access to raw materials make sure that the production timeframes are also optimized which helps manufacturers to maintain their competitive advantage. Export-driven growth has also been an important factor, with Malaysian die casting companies supplying precision components to markets that are located in Asia, Europe, and the Americas.

Sustainability is a key aspect for die casting firms in Malaysia and is a sign of their commitment to environmental responsibility. Many manufacturers are adopting eco-friendly methods, like recycling metal scraps, and employing energy-efficient machinery. Making use of lighter materials like aluminum and magnesium is also a major factor in sustainability because these materials reduce the amount of energy used in the final items they're used in including cars. Malaysian firms are also looking into methods to reduce the carbon footprint of their production. the carbon footprint of their products. By prioritizing green manufacturing, the industry aligns itself with global environmental standards as well as meeting the growing need for products that are sustainable. To gather additional details kindly look at Senadiecasting

Sustainability is an emerging focus for the Malaysian die casting industry, in which companies are working to make their operations more compatible with global environmental standards. Efforts to reduce energy consumption, minimize waste, and make use of recycled materials are growing in popularity. In the adoption of closed loop techniques, that recycle energy and other materials in the production process, exemplifies the company's commitment to resource efficiency. These initiatives not only reduce environmental impact but also contribute to cost savings, making sustainability a win for both the business and the environment. In focusing on environmentally friendly manufacturing, Malaysia's die casting business is positioning itself as a responsible and forward-thinking player in the global market.

Die casting is an integral part of Malaysia's manufacturing sector, aiding in innovation, efficiency as well as sustainability. The versatility and accuracy of it make it indispensable for a broad range of industries, from aerospace and automobiles to consumer electronics. With a strong focus on technology advancement, efficient labor force, and sustainability, Malaysia has positioned itself as an industry leader in the world market for die casting. In a time when the demand for premium precisely engineered and precision-engineered products is increasing as well, Malaysia's Malaysian Die casting business is poised to take on a greater role in shaping the future of manufacturing, delivering cutting-edge solutions that are able to meet the requirements of an ever-changing world.